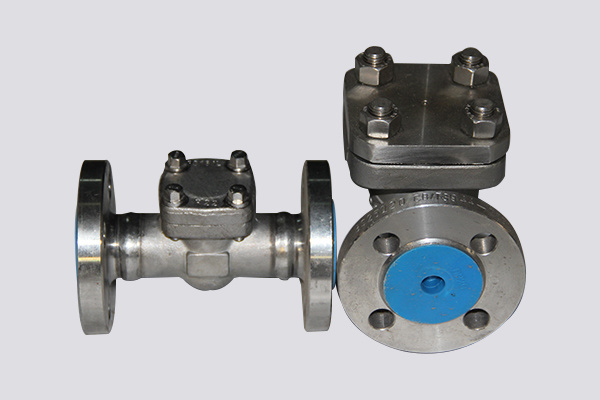

Four Functions of a Thermostatic Trap

- Air and water removal: The pressure or gravity of the pipeline causes the valve to open, quickly removing air and water, and shortening the heating time.

- Steam blocking: Steam entering the valve chamber causes the bimetallic element to bend, generating thermal tension and overcoming the pipeline pressure to close the valve ball. The thermal tension varies with the corresponding saturated steam curve. Therefore, it works effectively within its pressure range.

- Condensation discharge: Condensate gradually reduces the thermal tension of the bimetallic element, causing the discharge port to gradually open, allowing the condensate to be discharged smoothly.

- Check valve function: The valve ball can immediately close the discharge port when backflow occurs in the pipeline, without the need for additional devices.

Performance Specifications

| Product Model | Working Pressure MPa | Maximum Operating Temperature ℃ | Discharge Port Diameter (in) | Continuous Condensate Discharge (kg/h) | ||||||||||

| Inlet/Outlet Pressure Difference MPa | 0.035 | 0.1 | 0.2 | 0.35 | 0.52 | 0.7 | 1.05 | 1.4 | 2.1 | 2.8 | ||||

| TSF-1 | 0~1.4 | 260 | 3/8 | Condensate (subcooling) 22℃ | 286 | 431 | 612 | 748 | 816 | 907 | 1043 | 1202 | ||

| TSF-2 | 0~2.8 | 1/3 | 204 | 295 | 386 | 476 | 567 | 658 | 726 | 816 | 907 | 1021 | ||

| TSF-3 | 0~2.8 | 454 | 1/4 | 100 | 147 | 200 | 245 | 284 | 318 | 363 | 420 | 499 | 590 | |

| SF-1 | 0~0.35 | 260 | 3/4 | 998 | 1542 | 2041 | 2495 | |||||||

| SF-2 | 0~1.4 | 1/2 | 544 | 771 | 998 | 1225 | 1361 | 1497 | 1724 | 1996 | ||||

| SF-3 | 0~2.8 | 454 | 3/8 | 263 | 397 | 567 | 703 | 794 | 885 | 1021 | 1179 | 1338 | 1497 | |

Materials Table

| NO. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| Parts ARTS | Valve Body | Filter Screen | Valve Core Frame | Gasket | Bolt | Bimetallic Strip | Adjusting Nut | Valve Stem | Valve Cover | Gasket | Ball |

| Specification SPEC | WCBCF8CF8M | 304 | ZG1Cr13 weld-overlay STL | 1Cr18Ni9 flexible graphite | 42CrMo 304 316 |

B1 MB18 | 304 | 316L | WCB CF8 CF8M |

1Cr18Ni9 flexible graphite | 9Cr18 |

Keyword

drain valve

Air and water discharge: The pressure or gravity of the pipeline causes the valve to open, quickly discharging air and water, and shortening the heating time.

Steam blocking: The steam entering the valve chamber causes the bimetallic element to bend, generating thermal tensile force and overcoming the pipeline pressure to close the valve ball. The thermal tensile force changes with the corresponding saturated steam curve. Therefore, it can work effectively within its pressure range.

Condensation discharge: Condensation gradually reduces the thermal tensile force of the bimetallic element, causing the discharge port to gradually open, allowing the condensation to be discharged smoothly.

Check valve function: The valve ball can immediately close the discharge port when backflow occurs in the pipeline, without the need for additional devices.

Contact us

Category